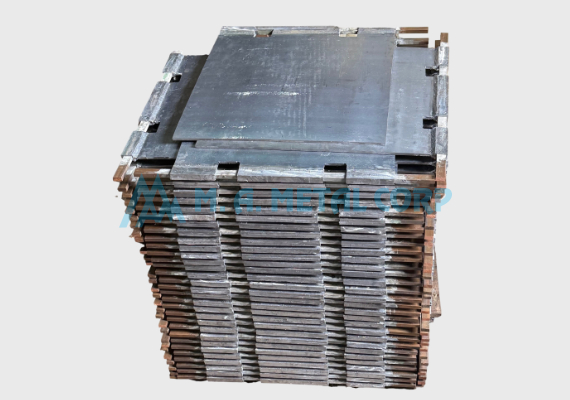

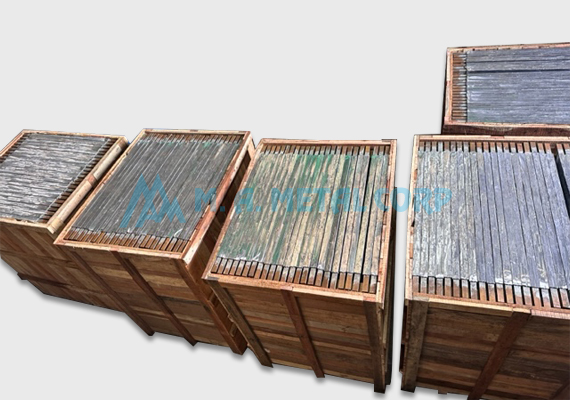

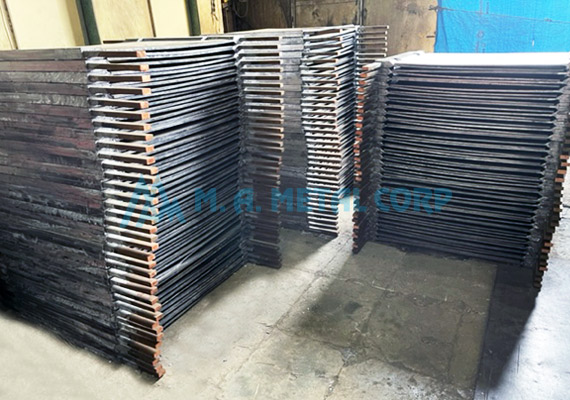

Lead Anodes

We manufacture high quality lead anodes, using premium quality lead as the raw material to ensure that it is free from any impurity, and hence offer excellent conductivity (flow of current) during electrolysis.

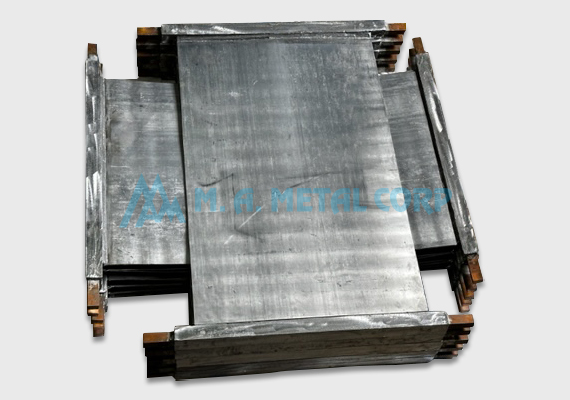

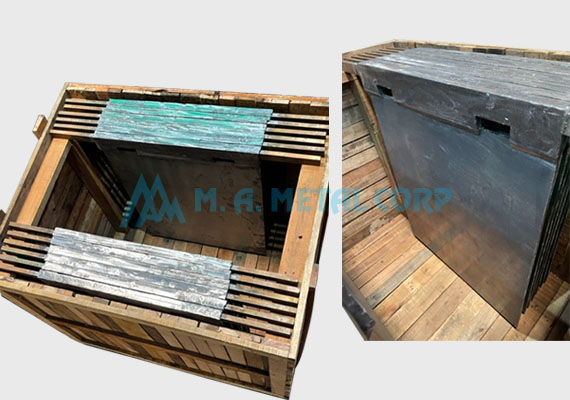

We manufacture custom-designed lead anodes using Lead-Silver alloys or as per the specific requirement of our customers. Some of the highlights of our lead-based anodes manufacturing capabilities are listed below:

- Lead anodes generally consist of Silver, Tin or Antimony, depending on the end use

- We offer the complete range of lead anodes – Extruded, Baskets, Grids and Hooks

-

We have developed capabilities to offer various shapes over the years. Following are some of the standard extruded configurations:

- Round

- Square

- Rectangle

- "D" Type

- Oval

- Elliptical

- Saw tooth

- Ribbed

- Zigzag

- Any other custom-shape can be developed as the customer needs

- Lead Anodes are usually offered with Copper or Bronze hooks coated with Plastisol in a color specified by the customer

- Anodes as per drawings provided by the customer

Applications of Lead Anodes

- Electro Winning / Electro Extraction Lead Anodes are used by the Electro wining industry in their acid cells.

- Plating High anti-corrosion properties of lead anodes make it the ideal choice for plating metals like Zinc, Nickel, Copper, Manganese, etc.

- Zinc Smelting Zinc Smelting is the process of converting zinc concentrates (ores that contain zinc) into pure Zinc. The most common process of Zinc Smelting is by Electrolysis, where lead anodes are widely used.